Scientists at MIT and Caltech have created a nanoengineered material that could be harder than the similarity kevlar or steel. Made from interconnected carbon “tetrakaidecahedrons,” the material taken in the effect of microscopic bullets in magnificent fashion.

The research study, led by MITs Carlos Portela, aimed to discover whether nanoarchitected products– that is, developed and fabricated at the scale of nanometers– could be a feasible path toward ultratough blast guards, body armor and other protective surfaces.

The idea of tetrakaidecahedron-based materials, however, isnt a new one. The complex 14-sided class of polyhedron (there are about 1.5 billion possible variations) was proposed by Lord Kelvin in the 19th century as theoretically one of the most effective possible for filling area with duplicates of itself.

If lots of such polyhedra can be packed into a small area and interconnected, Portela and his associates wondered, would they function as an effective shock absorber? Such materials had been checked with slow deformations however not powerful impacts like you would get out of a bullet or micrometeoroid.

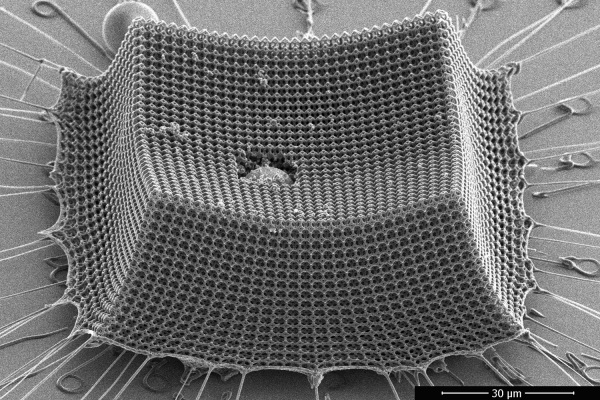

To learn, they assembled blocks of the material by methods of nanolithography strategies, baking the resulting structure till it was pure carbon. Then they shot these carbon structures with 14-micron-wide silicon oxide bullets taking a trip well above the speed of noise (however at these scales, the contrast is a bit quaint).

Image Credits: MIT/Caltech

The carbon structures, especially denser ones, soaked up the impact incredibly well, stopping the particle dead– and crucially, warping however not shattering.

” We show the material can soak up a great deal of energy since of this shock compaction system of struts at the nanoscale versus something thats monolithic and fully dense, not nanoarchitected,” said Portela in a press release describing the discovery. “The very same quantity of mass of our material would be far more effective at stopping a projectile than the exact same quantity of mass of Kevlar.”

Remarkably, the researchers found they were able to design the impact and damage best by utilizing approaches usually utilized to explain meteors affecting a worlds surface.

This is simply a preliminary laboratory outcome, so soldiers will not be wearing tetrakaidecahedronal flak jackets any time soon, but the experiment absolutely shows the promise of this approach. If the team has the ability to discover a way to manufacture the product at scale, it might be helpful in all kinds of industries.

The study was published in the journal Nature Materials.